Quality First

Our Quality Department employs a combination of state-of-the-art equipment, rigorous testing protocols, and highly trained personnel to maintain the highest levels of quality assurance throughout the manufacturing process. This dedication to quality ensures that ASAŞ products consistently meet or exceed customer expectations and industry standards.

ASAŞ's State-of-the-Art Laboratory for Quality

We are committed to delivering high-quality products across various industries, boasts a cutting-edge laboratory dedicated to quality. This laboratory serves as the cornerstone of ASAŞ’s commitment to excellence, ensuring that every product leaving our facility meets stringent quality standards.

Here is an overview of our laboratory:

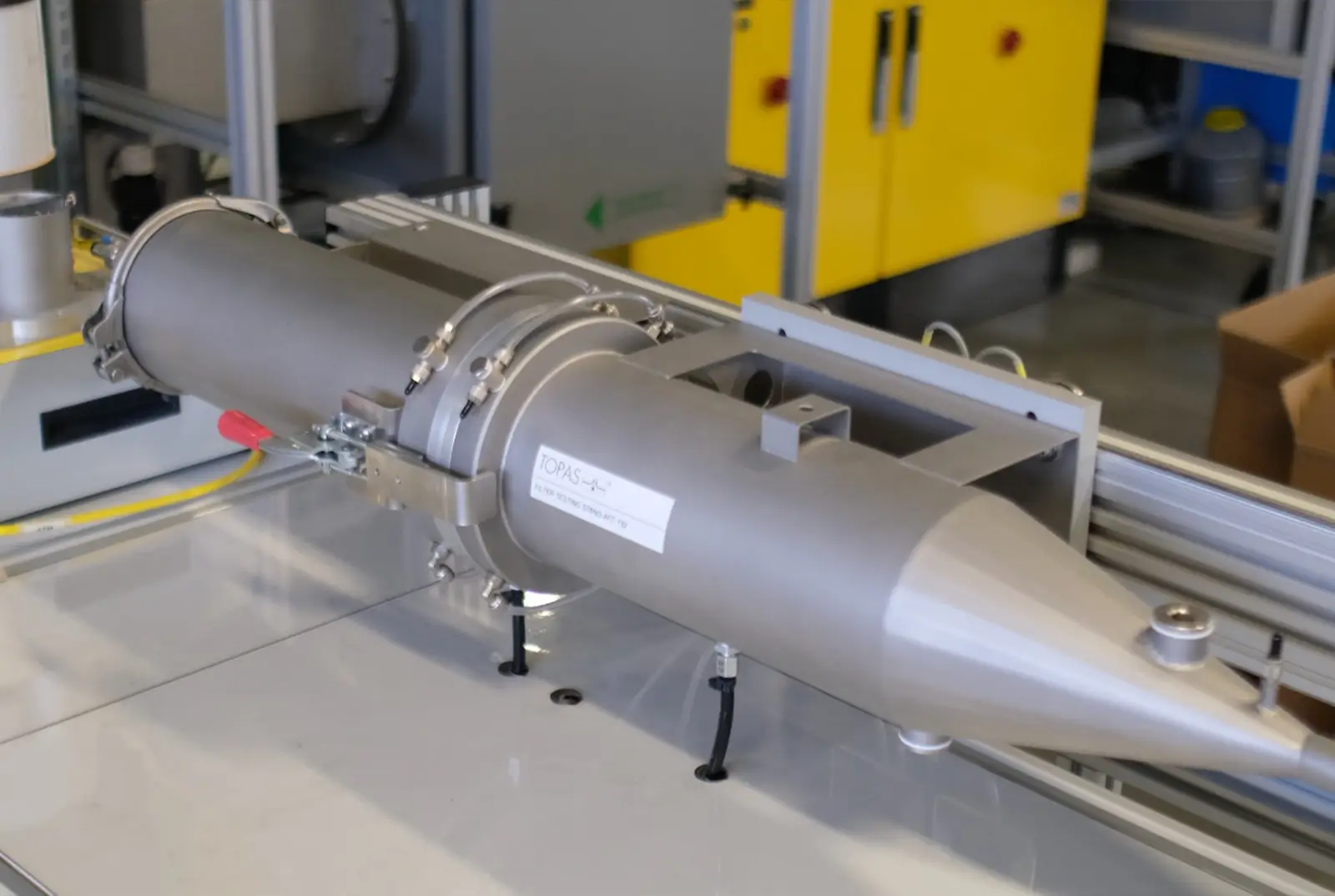

Cutting-Edge Equipment

ASAŞ has invested significantly in advanced laboratory equipment to facilitate precise and accurate quality assessments. This includes state-of-the-art testing machines, measurement instruments, and analytical tools tailored to the specific needs of the industries it serves.

Highly Skilled Personnel

The laboratory is staffed with a team of highly trained and experienced engineers, technicians, and quality control specialists. These experts are well-versed in industry best practices and are dedicated to maintaining the highest levels of quality in ASAŞ's products.

Comprehensive Testing Capabilities

The laboratory conducts a wide array of tests and analyses to assess the quality and performance of materials, components, and final products. These tests cover areas such as material properties, product durability, filtration efficiency, and more.

Raw Material Assessment

ASAŞ's laboratory rigorously evaluates incoming raw materials to ensure they meet specified quality standards. This includes measurements of physical, chemical, and mechanical properties to verify suitability for use in ASAŞ products.

Product Performance Evaluation

ASAŞ conducts comprehensive tests to assess how its products perform under various conditions. This includes evaluating filters for efficiency, durability, and reliability in real-world applications.

Data-Driven Decision-Making

The laboratory generates vast amounts of data during testing and analysis. This data is instrumental in making informed decisions about product quality, process improvements, and compliance with industry standards.

Quality Control Protocols

ASAŞ has implemented stringent quality control protocols to monitor and ensure consistent quality throughout the manufacturing process. This includes in-process inspections and final product audits.

Certifications and Compliance

ASAŞ's laboratory plays a crucial role in obtaining industry certifications and ensuring compliance with international standards and regulations. This helps the company meet the diverse and rigorous requirements of its customers.

Continuous Improvement

ASAŞ places a strong emphasis on continuous improvement. The laboratory is involved in ongoing research and development efforts to enhance product performance and quality, staying at the forefront of industry advancements.

Customer-Centric Approach

ASAŞ's laboratory is dedicated to meeting customer specifications and exceeding their expectations. Customized testing and analysis are conducted as needed to address unique customer requirements.

Environmental Responsibility

ASAŞ takes environmental responsibility seriously. The laboratory ensures that products meet eco-friendly standards and contribute to sustainability goals.

Safety Measures

Safety is a top priority in the laboratory. Stringent safety measures are in place to protect personnel and maintain the integrity of test results.

ASAŞ’s great laboratory for quality embodies the company’s unwavering commitment to delivering products of the highest quality. Equipped with cutting-edge technology, staffed by experts, and guided by rigorous protocols, this laboratory is at the heart of ASAŞ’s quality assurance efforts, ensuring that its products consistently meet the demanding standards of its diverse customer base.

OUR TEST STANDARDS

LIQUID FILTRATION TESTS

- Pressure Difference tests

- Dirt Holding Capacity test

- Filtration Efficiency test

- Collapse Test

- Bubble Test (First bubble test)

- Pulse pressure test (for Spin-On Filters)

- By-Pass valve opening test

- Anti-Drain valve leak test

- Static burst test (for Spin-On Filters)

- Other tests and aging tests

DRY FILTRATION TESTS

Inlet air cleaning equipment for internal combustion engines and compressors– ISO 5011

- Pressure Difference tests

- Dust Holding Capacity test

- Initial Filtration Efficiency test

- Final Filtration Efficiency Test

- Water Separation Test (for Vented Air systems)

- Test Powders;

- AC-Fine

- AC-Coarse

Particulate Filtration– DIN 71460‐1

- Pressure Difference tests

- Dust Holding Capacity test

- Initial Filtration Efficiency test

- Final Filtration Efficiency Test

- Test Powders;

- AC‐Fine

- KCL

- DESCH

Cabin Odor Air Filters – DIN 71460‐1

- Pressure Difference tests

- Adsorption / Desorption test

- Test Gases;

- Toluene – 80 ppm

- SO2 ‐ 30 ppm

- n-Butane – 80 ppm

MEDIA TESTS

- Grammage test

- Air Permeability Test

- Thickness measurement test

- Paper burst test

- Pore size test

- Flammability test

- Sheet Media Performance test

SHEET MEDIA TESTS

- Pressure Difference tests

- Dust Holding Capacity test

- Initial Filtering Efficiency test

- Final Filtration Efficiency Test

- Test Powders;

- Fine

- AC‐Coarse

- AC‐Medium

- DESCH