Air filters are essential components in the automotive sector, serving a crucial role in maintaining the health and efficiency of internal combustion engines. These filters are designed to trap and prevent airborne contaminants, such as dust, pollen, and debris, from entering the engine’s intake system. By ensuring that only clean and filtered air reaches the engine, air filters contribute to optimal combustion, improved fuel efficiency, and the overall longevity of the vehicle. Regular replacement of air filters is vital to sustaining peak engine performance and preventing potential damage to sensitive engine components.

At ASAŞ, we take pride in producing high-quality air filters tailored to the diverse needs of the automotive sector. Our air filter lineup includes two main types: heavy-duty filters and panel filters. The heavy-duty filters are designed to withstand challenging operating conditions, making them suitable for commercial vehicles, construction equipment, and industrial machinery. On the other hand, our panel filters are crafted for passenger cars and light-duty vehicles, providing efficient filtration for everyday driving. With a commitment to precision engineering and adherence to rigorous quality standards, ASAŞ air filters not only meet industry requirements but also contribute to enhanced engine performance and environmental sustainability.

Heavy Duty Air Filters

Heavy-duty air filters are essential components used in the air intake systems of large and powerful engines, such as those found in commercial trucks, construction equipment, industrial machinery, and agricultural vehicles. These filters play a critical role in maintaining engine performance and preventing damage by removing airborne contaminants from the incoming air. Here’s some brief information about heavy-duty air filters:

Design: Heavy-duty air filters are typically larger and more robust than standard automotive air filters due to the higher airflow requirements and the larger engines they serve. They are commonly designed as cylindrical or rectangular units and are housed in sturdy metal or plastic casings.

Filtration Medium: Inside the filter housing, there is a high-efficiency filtration medium, often made of pleated paper, synthetic materials, or a combination of both. This medium is designed to trap and hold a wide range of contaminants, including dust, dirt, pollen, and even larger particles like insects.

Function: As air is drawn into the engine for combustion, it passes through the heavy-duty air filter. The filter captures and retains contaminants, preventing them from entering the engine. Clean, filtered air is then supplied to the engine’s intake manifold, ensuring efficient combustion and minimizing wear and tear on engine components.

Maintenance: Proper maintenance is crucial for heavy-duty air filters, as they operate in environments with higher levels of dust and debris. Regular inspections and replacement are necessary to ensure that the filter remains effective in protecting the engine.

Benefits: Heavy-duty air filters help maintain optimal engine performance and longevity by preventing abrasive particles from entering the engine. They contribute to improved fuel efficiency, reduced emissions, and longer service intervals for heavy-duty equipment.

Environment-Specific Filters: Some heavy-duty air filters are designed for specific environments, such as construction sites or agricultural fields. These filters may include additional features to handle extreme conditions, such as moisture-resistant properties or specialized coatings.

Compatibility: Heavy-duty air filters are available in various sizes and configurations to fit different engine types and equipment models. It is essential to use the correct filter size and type recommended by the manufacturer to ensure proper filtration and compatibility.

Customization: Some heavy-duty air filters can be customized with additional layers or coatings to meet specific performance requirements or to address unique operating conditions.

In summary, heavy-duty air filters are vital components in the air intake systems of large engines used in commercial and industrial applications. Their robust design and high-efficiency filtration help protect the engine, ensuring optimal performance, longer engine life, and reduced environmental impact through cleaner emissions. Regular maintenance and proper filter selection are essential for maximizing their effectiveness.

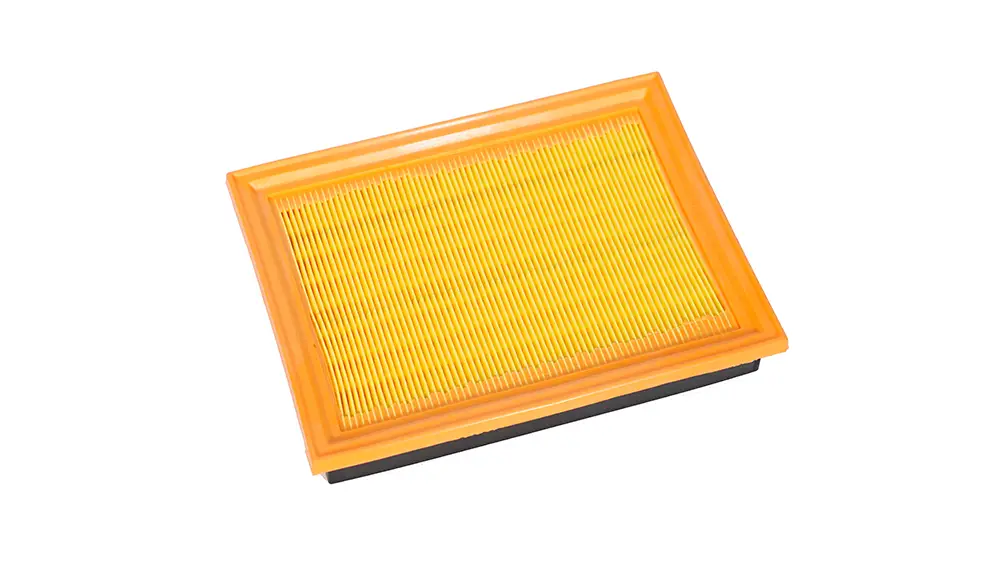

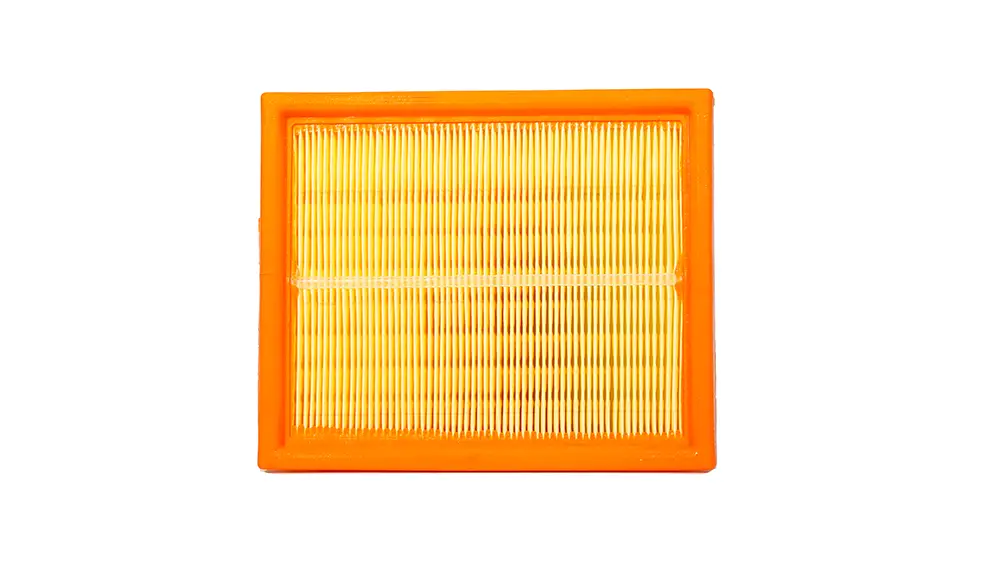

Panel Air Filters

Panel air filters used in the automotive industry are designed to filter the air entering a vehicle’s engine, ensuring it is clean and free from contaminants. These filters play a crucial role in maintaining engine performance, fuel efficiency, and the overall longevity of the vehicle. Here’s some brief information about panel air filters used in the automotive industry:

Design: Automotive panel air filters are typically flat, rectangular or square in shape, and constructed using pleated or layered filter media. They are designed to fit into the air filter housing located within the engine compartment.

Filtration Media: The filter media used in automotive panel filters is engineered to capture and retain various airborne contaminants, including dust, dirt, pollen, insects, and other particles. The efficiency of these filters can vary based on the filter’s design and the quality of the filtration material.

Function: As the vehicle’s engine draws in air for combustion, it passes through the panel air filter. The filter captures and retains the contaminants present in the air, preventing them from entering the engine. Clean, filtered air is then supplied to the engine, ensuring efficient combustion and reducing the risk of damage to internal components.

Maintenance: Regular maintenance of automotive panel air filters is essential to ensure engine performance and fuel efficiency. Filters should be inspected and replaced as needed, following the manufacturer’s recommended maintenance schedule.

Improved Engine Performance: A clean panel air filter allows for optimal airflow into the engine, which is essential for efficient combustion. Improved airflow can lead to better engine performance, increased power output, and enhanced fuel efficiency.

Environmental Impact: Some panel air filters used in the automotive industry are designed to be eco-friendly, featuring recyclable materials and sustainable production practices, reducing their environmental footprint.

Aftermarket Options: Many vehicle owners have the option to choose aftermarket panel air filters, which may offer improved filtration efficiency or performance compared to standard OEM (Original Equipment Manufacturer) filters.

Custom Sizing: Panel air filters for vehicles are typically available in a range of sizes to fit different makes and models. It’s important to select the filter size that matches the specific vehicle’s air filter housing.

DIY Replacement: Replacing an automotive panel air filter is a straightforward DIY task for many vehicle owners, and it does not usually require specialized tools or professional assistance.

In summary, panel air filters used in the automotive industry are essential components that help maintain engine performance, fuel efficiency, and air quality within the vehicle cabin. Regular inspection and replacement are vital to ensure these filters continue to function effectively and contribute to the overall health of the vehicle’s engine.